What to expect from facility management software

XR Scan: Digital measurement app for facility management

Digitization in facility management is only slowly gaining momentum. According to a recent german study by the market research company Lünendonk & Hossenfelder, two obstacles continue to play a major role: a lack of knowledge of the possibilities of facility management software on the one hand and a lack of precise solutions on the other. Measurement processes are exemplary in this respect, and XR Scan's pioneering solution approach is now clearing the way for SMEs as well.

Whether in the construction phase, for preparing offers or updating inventory documentation - in facility management, as in so many other industries, measurements are regularly required. This is a recurring, mammoth task, which can be shortened and simplified considerably by automatic recording of windows, doors, tables or floor areas when a suitable facility management software is implemented correctly. Why have digital solutions not yet become established here?

Too cumbersome, too expensive

The devices and solutions currently in use range from the simple folding rule to the handheld laser to digital partial solutions that use 3D lasers and lidar sensor technology. The spectrum of results is correspondingly large, from a simple distance measurement to an almost infinitely large point cloud. What they have in common, however, is that none of the methods produces directly usable results: measurements taken by hand have to be laboriously incorporated into existing models, often with a high error rate, while point clouds require labor-intensive post-processing by specialists - only then can the data be assigned to specific objects. In the course of a measurement, days rather than weeks pass before the data can be used for further planning, calculations or the preparation of offers.

In contrast, it is no wonder that Lünendonk & Hossenfelder identified digitized solutions in the area of CAFM and BIM as a clear wish of the facility managers surveyed.

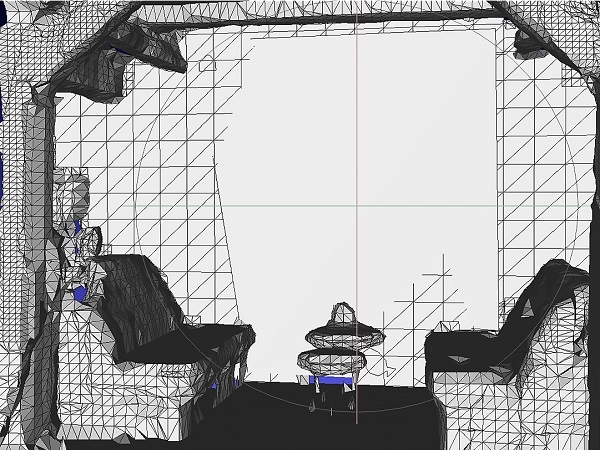

Create intelligent 3D models

Developed end-to-end, the XR Scan measurement solution addresses precisely these pain points with a fully digitized planning measurement that is fundamentally simplified and shortened. Here, too, a LiDAR scanner is used, but instead of point clouds it generates an "intelligent" 3D model - only the measurement data that is actually needed is supplied. Thus, the ideal facility management apps awaits.

In addition to end-to-end implementation, the development focused on the app concept for measurements at the push of a button. XR Scan is managed independently by customers in the Spacific Solution Portal, using Azure Cloud Services.

- After the measurement job has been created and the objects to be measured have been defined, it is assigned to the respective employee.

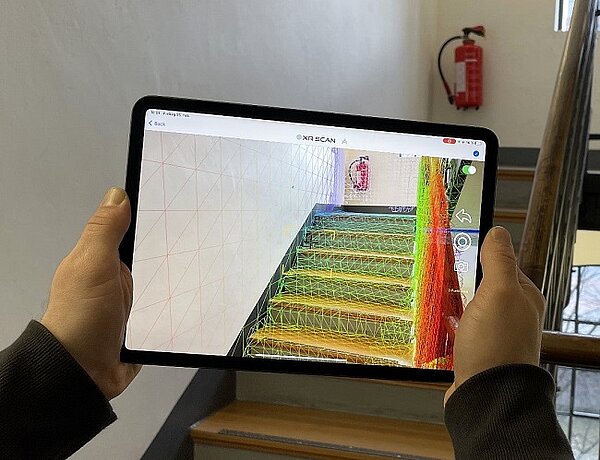

- The actual measurement can be performed via various devices (iPhone, iPad or HoloLens), even offline.

- If CRM systems are used to evaluate the results, the data can also be imported into the portal via API to avoid duplicate work steps.

After opening the FM app, the employee starts the digital recording of the environment, simply by walking on the premises or even outdoor environment. He also sets measuring points for the requested objects - for example, for table surfaces, windows, electrical lines or sockets. The results can then be transferred directly back to the portal, where they, including measurements, are immediately available as a 3D model and can be transferred to third-party systems in an output format of choice.

Planning and getting measurements besomes much easier and faster for facility managers. The elimination of post-processing means that specialists are no longer unnecessarily tied up, and the measurement itself consists of guided workflows that require neither prior knowledge nor extensive training. Since XR Scan was developed as a flexible and easy-to-implement standard solution that requires neither complex development nor complicated integration into the respective IT systems, digitized measurement is now also available to companies for which individual solutions in this area are not worthwhile.

The accuracy of XR Scan as a facility management software meets the requirements of industrial production and is therefore ideally suited for measuring rooms and objects. Other solutions deliver more accurate results in parts and even manage to reach the macrometer range, for example, but due to the limitations described above, they are clearly overengineered for this use case.

Another example from the field:

A stairlift manufacturer is in contact with a potential customer. With XR Scan, he can now measure the staircase in just a few minutes during the first visit and directly start planning for the required rails on the basis of the instantly generated, intelligent 3D model. This means that the customer receives a concrete offer tailored to his needs much faster.

In two areas, planning measurement is indispensable in the field of facility management: on the one hand, as a calculation basis in the course of building planning or the takeover of new projects, and on the other hand, for updating as-built documentation - for example, when it comes to the management of office complexes with a frequently changing room structure.

However, many other industries can also look forward to both faster and more accurate measurement with XR Scan: In the real estate sector such as construction, in the area of technical building equipment or in the course of documentation, for example for insurance companies, providers are faced with the same problem. Accurate measurement is also indispensable within production processes or in logistics.

Learn more

For more information on digitized measurement with XR Scan, please visit our product page. Furthermore, you have the possibility to test the solution for 14 days free of charge after registering in the portal.

If you still have questions, please do not hesitate to contact us via the contact form - we are at your disposal!