Why AR is so important for the industry

Augmented reality may be the talk of the industry, but it is far from having arrived in all business processes. It is undisputed that AR is advancing production and manufacturing: From the visualization of workflows to training in mixed reality to more convincing trade show presentations, there is hardly anything that the new all-purpose weapon augmented reality cannot do. In the following, we not only want to reveal to you the possible applications, but also how easy it is to get started with AR in manufacturing and production with standard solutions!

From 0 to augmented reality at the touch of a button

COTS instead of individual solution: Get started right away without development work! The end-2-end business process solutions from Spacific are flexible and scalable AR standard solutions for produrction and manufacturing, compatible with all common data formats and easily interfaced with third-party systems. With an off-the-shelf solution, your company can start using augmented reality tomorrow, without investment or interface issues.

Augmented Reality in app format: Intuitive and clear - Spacific's AR solutions require neither specialists nor training or special equipment and are available for iOS, Android and data glasses. Orders are created in the backend, our solution platform, and can be implemented immediately in production.

AR in manufacturing:

Uses + examples

Augmented reality helps in manufacturing and production on the one hand to capture objects and situations digitally in the most accurate way, and on the other hand it enables the display of even complex models in any environment. So while digital measurement with XR Scan can create intelligent 3D models of entire rooms at the touch of a button as the basis for planning and calculations, the visualization software XR Scene App for complex AR scenes and XR Scene Web for AR experiences in the browser display 3D objects and information as desired - for guided workflows, for training, for marking danger zones or for presentation at trade shows.

One of the most important areas of application here is the use of machine data from the IoT or the IIoT. By connecting to an IIoT platform such as that of Adamos, process and machine data is collected, evaluated and made available to users as intuitive, pictorial instructions in mixed reality for faster and safer work processes.

Training & Education

It is a great help to be able to visualize processes vividly and realistically at any time so that every move is correct. The integration of virtual 3D objects in any environment enables faster and more intensive learning. In addition, training can be designed particularly flexibly due to the fact that it can be carried out and repeated at will - without having to block systems or machines for this purpose. This saves time and significantly reduces costs at the same time.

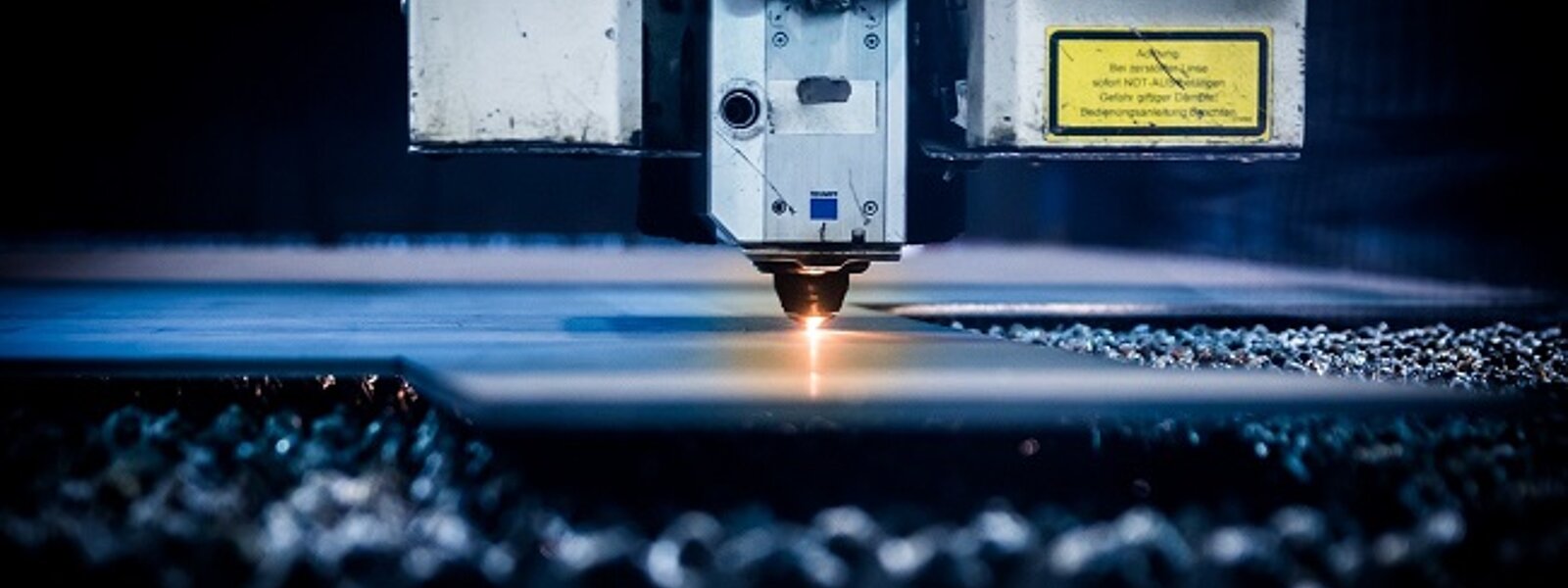

In production & assembly

The important information where it is needed: Which step comes next, where does the weld seam have to be set? In particular, anyone who can see both reality and the additional virtual information at the same time with data glasses such as HoloLens 2 not only saves time, but also avoids mistakes.

As part of the Adamos platform and thus the IoT, XR Scene App enables the perfect AR visualization of machine data, from the detail to the digital twin of an entire factory. There are no limits to the possible applications - and it's very straightforward at the push of a button:

- Assemble 3D objects and information into a scene

- anchor at fixed points or use in any environment

- share with employees

- use virtual extensions at will

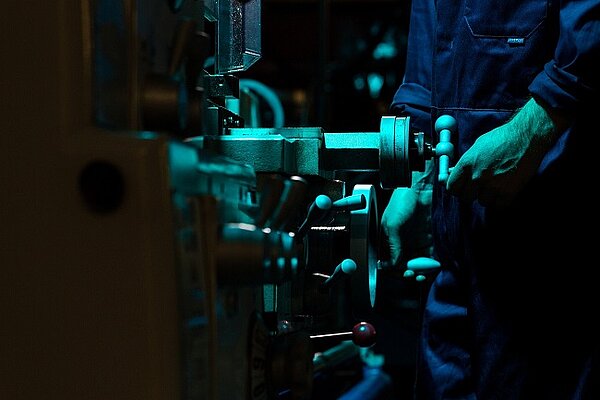

Maintenance & Inspection

Thanks to augmented reality, the foreman is always with you in production: Whether work processes, finished model or further information, your employees now have everything important in front of their eyes at all times - with a smartphone, tablet or hands-free with a HoloLens. With virtual content and remote support, guided processes in maintenance and assembly increase safety and reduce error rates, time and costs.

Factory Planning

With regard to the design of large facilities or a factory, the advantages of several Spacific solutions are open to you:

- XR Scan simplifies and accelerates accurate as-built documentation, the environment to be built is scanned completely digitally and converted into an intelligent 3D model. At the touch of a button, this provides you with an accurate as-built dimension, also for updating documentation during the construction phase.

- XR Scene App and XR Scene Web enable the convincing visualization of the planned plant or factory to the customer: 3D models such as that of the surroundings to be built or of the project can be experienced in Mixed Reality anytime and anywhere. For example, you can display the planned factory close enough to touch on site or use the detailed models as you wish for an impressive presentation.

More AR industry solutions

Augmented Reality is not only excellent for use in production, it also shines in many other industries! Feel free to take a look at our constantly growing list of field-tested applications. If you have any questions or would like a personal quote, don't hesitate to contact us, our AR experts are always at your disposal.